The Strategic Imperative of Custom Cosmetic Boxes for Brand Efficacy and Product Integrity

In highly competitive and beauty -operated cosmetics industry, packaging products transfer their fundamental role of control.

Introduction

In highly competitive and beauty -operated cosmetics industry, packaging products transfer their fundamental role of control. Custom cosmetic boxes have emerged as an important strategic property, material science, design engineering, and avail advanced printing techniques to give versatile benefits. This analysis will clarify the technical and marketing benefits provided by the bespoke packaging solutions, showing why the custom boxes are unavoidable for brand discrimination, product protection and enhanced consumer engagement in the cosmetics sector.

Optimizing Product Preservation through Engineered Packaging Solutions

The primary technical mandate of any packaging is to ensure product integrity from the point of manufacture to consumer use. Custom cosmetic boxes fulfill this by:

Bespoke Structural Design: Engineer tails these custom boxes as a factor of properly dimensions and specific cosmetic items – this delicate glass serum bottles, compact or lipstick tubes. This reduces internal movement during accurate transit and handling, reducing the risk of rupture, leakage or cosmetic damage. Companies use durable paperboard substrates (eg, solid-botidly sulfate-SBS) or rigid constructions, which often include custom-designed inserts or cushioning elements (eg di-cut foam or molded pulp), so that products can be ensured to ensure the products to get into ancient, marketing conditions. This scientific approach to fit and safety is paramount, especially for high-value or delicate cosmetic yogas.

Amplifying Brand Resonance and Achieving Market Differentiation

Beyond protection, Custom Cosmetic Boxes serve as a powerful conduit for brand communication and a primary tool for market differentiation:

- Brand recognition and recognition: In a saturated market, custom-crushed boxes provide a tangible canvas for brand expression. Unique color straps (often pantone-3 for stability), specific logotypes, Bispok typography, and the strategic application of branding elements in a product line constantly converts the box into a immediate brand identifier. This visual stability creates recognition and recalls the consumer, which distinguishes the brand from competitors on crowded retail shelves and on digital unboxing experiences.

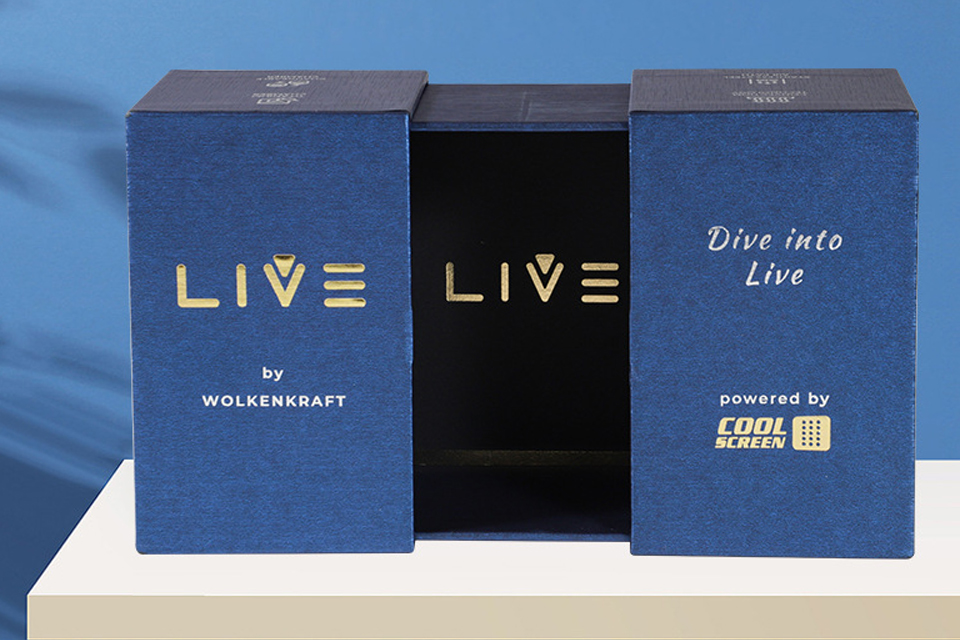

- Increasing the perceived product value: Custom cosmetic box touch and visual quality affects consumer perception. Selection of premium materials, combined with sophisticated custom-affected boxes, which is characterized by finish, such as matte or gloss lamination, spot UV, Embossing, Debossing, or Foil Stamping, enhances the perceived price of the attached cosmetic product. This “premiumment” effect can make high value points correct and appoint the brand as one of the quality and luxury, which affects purchasing decisions.

The Science of Material Selection and Finishing Techniques for Cosmetic Appeal

The efficacy of custom cosmetic boxes lies deeply in the artistic application of science and finishing techniques of material selection. Substrates such as high-grade paperboard (eg, C1s or C2S folding box-board-FBB), craft paper for an environmental-conscious appeal, or luxurious rigid boards are selected on the basis of structural requirements, printability and desired beauty. For example, a dense, smooth paperboard provides an excellent surface for high-loyal offset or digital printing.

In addition, finishing processes are not only decorative; They contribute to the durability and sensory appeal of the box:

- Lamination (Matt/Gloss): Provide a protective layer against moisture and scorching during changing the touch feel.

- Spot UV: creates a local high-gloss effect, which attracts attention to specific design elements such as logo or product name.

- Embossing/Debossing: A three-dimensional additions adds, increases touching engagement and expresses sophistication.

- Forest Stamping: Introduction to metal elements, indication of luxury and premium quality. These scientificly applied carefully applied on the selected materials and custom-print boxes work in coordination to create a packaging solution that is functionally strong and aesthetically compelling, which directly affects the consumer perception and brand image.

Leveraging Advanced Printing Technologies for Dynamic Cosmetic Packaging

Modern printing technologies have revolutionized the capabilities of custom-printed boxes, particularly within the dynamic cosmetics industry:

- High-loyal graphics and color accuracy: Offset lithography remains a gold standard for large-lecratory runs, which offers extraordinary color fidelity and image sharp to reproduce complex cosmetic branding. Digital printing, conversely, enables cost -effective short run and variable data printing. This allows brands to allow limited versions, individual custom cosmetic boxes, or packaging, which features seasonal designs without provoking prohibitive setup costs.

- Information proliferation and regulatory compliance: Custom boxes provide adequate surface area to express required product information. This includes component list, use instructions, batch codes, expiration dates and stability certificates, all of which can be originally integrated into the design using advanced printing methods. This ensures regulator compliance and enhances the consumer trust by providing transparent product details.

Comparative Advantages of Customization in Cosmetic Packaging

| Feature Category | Standard (Stock) Packaging | Custom Cosmetic Boxes (Bespoke) | Strategic Implication for Cosmetics |

|---|---|---|---|

| Product Fit & Protection | Generic sizes, often requires void fill | Precisely engineered to product dimensions; integrated cushioning options | Reduced damage, enhanced product integrity, minimizes need for extra packing materials. |

| Brand Identity | Limited branding, often label-dependent | Full control over design, color, materials, finishes; embodies unique brand aesthetic | Strong brand recognition, differentiation, consistent brand messaging, supports premium positioning. |

| Perceived Value | Basic, functional perception | High-quality materials and finishes create a premium, luxurious feel | Increased perceived product value, justifies premium pricing, enhances unboxing experience. |

| Marketing Impact | Minimal direct marketing capability | Acts as a “silent salesman,” conveys brand story, can include QR codes or promotional info | Extends marketing reach, turns packaging into an active brand communication tool. |

| Cost Optimization | May seem cheaper upfront, but can lead to higher damage rates or shipping costs due to poor fit | Optimized dimensions reduce material waste and can lower shipping (volumetric) costs; prevents product loss | Improved ROI through reduced damage and optimized logistics, despite potentially higher per-unit design/setup costs initially. |

Conclusion

Adoption of custom cosmetic boxes is not just a beauty option, but a calculation strategic decision that gives significant returns in product protection, brand equity and market performance. By taking advantage of bespoke design, material science, and advanced custom-affected box technologies, cosmetic brands can effectively secure their products, raise their unique identity, alleged price, and permanent customers can promote satisfaction. In an industry where presentation is paramount, Custom boxes provide the critical interface for transforming a product into a coveted brand experience.