Tariffs are striking the product packaging sector hard, interrupting every little thing from supply chains to packaging layout. But what does this mean for united state services that rely on customized product packaging to deliver their products? And more importantly, how can brand names stay prepared and reduce the financial impact?

It’s understandable for services to really feel perplexed in a transforming trade environment. This post puncture the sound to aid you make smarter, more critical product packaging decisions amid the recurring toll dilemma. Effect of Tariffs on Packaging Purchasers

Unexpected Price Walkings

Numerous small businesses wiht tighter spending plans have generally sourced directly from Chinese packaging producers as a result of their competitive pricing. However when U.S. President Donald Trump imposed a 145% tariff rate on Chinese products in very early April, packaging costs surged overnight. Given that the purchasers– the U.S. organizations– are accountable for paying these import duties, the economic problem struck fast and hard.

Even if you’re sourcing packaging from U.S.-based suppliers, you’re not entirely immune to tariff-related expenses. That’s because many neighborhood packaging business depend heavily on imported materials from China or make there. As the brand-new tariffs cause higher expenses in production, those increases are frequently passed down to their consumers, indicating your service still winds up bearing the cost.

Less Packaging Materials and Choices

Toll interruptions to worldwide supply chains are developing significant uncertainty in packaging supplies. Numerous product packaging business currently deal with logistics challenges in sourcing raw materials or shipping finished goods, which can leave you waiting on vital packaging orders– and ultimately, place your sales in jeapardy.

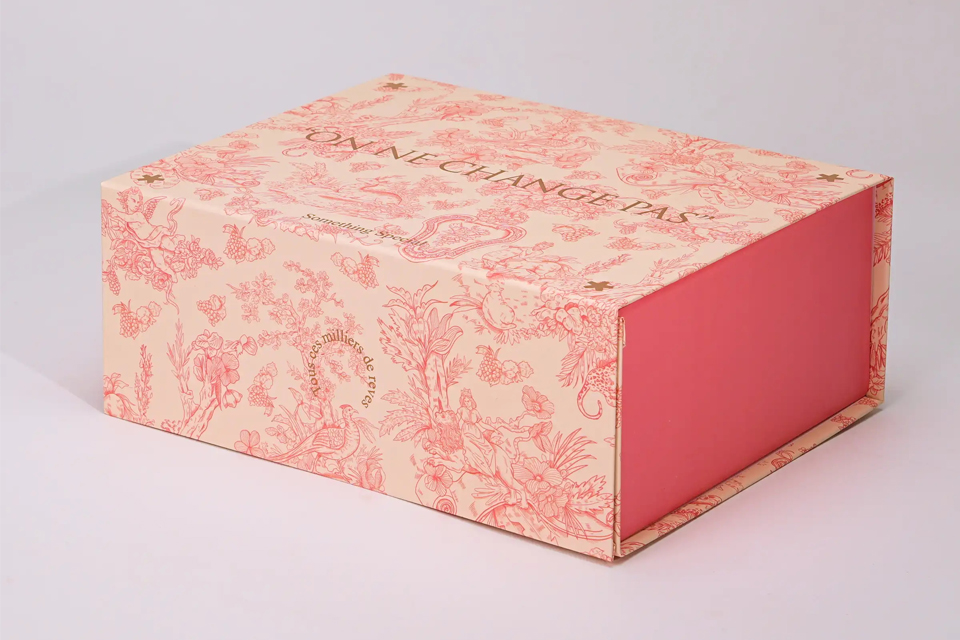

To handle minimal inventory, vendors may minimize the variety of product packaging options they provide. This suggests less customization choices for your brand. In addition to that, with earnings squeezed by tariffs, lots of custom packaging firms deal with existential hazards. AS even more vendors are forced to scale back or shut there doors, premium custom product packaging choices could become significantly limited for brand names.

Decline in Consumer Demand

With packaging costs climbing due to high tolls, numerous brand names are left with no choice however to increase costs. Regrettably, higher costs can decrease clients’ desire to buy, potentially hurting both sales and hard-earned customer commitment.

Economic experts alert that the recurring profession battle can trigger an economic crisis. The uncertainty bordering the global economy especially impacts demand for premium products with tailored packaging, as customers often tend to prioritize essential acquisitions during difficult financial times, making your investment in high-quality packaging less effective at driving sales.

What Organizations Can Do

1. Review Your Product Packaging Provider

If you’re currently acquiring packaging from China or from providers that only manufacture there, you might already be really feeling the stress to make a change.

As global trade dynamics continue to shift, your sourcing technique needs to progress accordingly. Cost alone should not be the making a decision aspect any longer. Dexterity and adaptability are just as vital. Look for suppliers with multiple production places across other nations. This gives you extra choices and and better stability when faced with abrupt tariff adjustments.

Openness is likewise essential. A great supplier should be open concerning their exposure to tariffs, their cost estimates, and the state of their supply chain. Ask the right questions:

What is their strategy for handling tolls? Do they have backup plans in position for long-lasting interruptions? The even more you know, the much better ready you’ll be to partner with a provider that can weather unpredictability together with your organization.

2. Supplier Cooperation and Arrangement

Whether you’re seeking choice vendors or sticking with your existing one, it’s essential to work together proactively to manage the cost increases triggered by tariffs.

Start by working out much more flexible contract terms, such as extended settlement timelines to aid ease cash flow pressures. You can additionally request quantity price cuts on bulk orders or discover packed solutions that help decrease your total expenses.

Bear in mind, a lot of product packaging business are dealing with the same obstacles in this unpredictable market. Open, truthful communication can result in options that profit both sides. A strong vendor connection improved transparency and partnership can aid both celebrations survive andd even grow throughout this difficult duration for the whole market.

3. Optimizing Packaging STyle

Past renegotiating distributor terms, owrk together with your packaging developer to strategically reorganize your product packaging for higher cost efficiency. Right here are a few techniques:

Lightweighting: Lower the density or weight of your packaging products. This not only reduces material use however can likewise minimize tariff direct exposure and delivery costs. Keep in mind, however, taht it might call for cautious testing to maintain sufficient item protection. Right-sizing: Change packaging measurements to better fit the item. By reducing excess product and void area, you can reduce both product expenses and dimensional delivery costs. Simplification: Improve your product packaging by utilizing fewer products or parts. This can help reduced production expenses, streamline setting up, and even enhance recyclability. Material alternative: Swap out materials for options sourced from low-tariff or tariff-free areas. For instance, changing to domestically sourced recycled products can promote sustainability while assisting manage costs. Whichever technique you take, it iwll likely call for extra R&D to make sure that your new layout preserves product honesty and straightens with your brand name criteria. Yet when done right, these adjustments can dramatically lower long-term packaging expenses.

4. Integrate Tariff Prices right into Preparation

Passing increased expenses directly to your clients may seem like the easiest option, yet it risks harmful customer satisfaction and hurting sales.

Instead, businesses should take a strategic approach. Element capacity volatility in packaging costs into your more comprehensive prices approaches, margin planning, and economic forecasts. This assists ensure your organization remains rewarding even as trade conditions shift.

Take advantage of forecasting devices– especially those powered by AI– to much better take care of product packaging supply. By anticipating need and and monitoring toll trends, you can put calculated orders in advance and prevent supply chain disturbances. Planning in advance offers you a competitive edge and helps secure your bottom line in unsure times.