Cost Considerations of Custom Colored Boxes

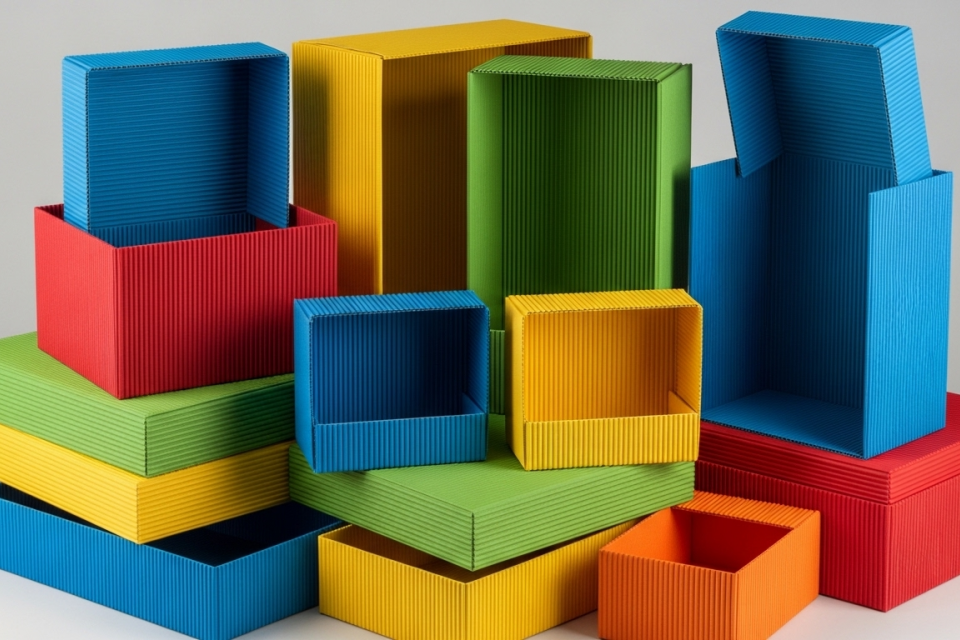

This guide details the costs of custom colored boxes, covering materials, printing, design, quantity, and sustainability for effective packaging budget management.

Summary

Custom colored boxes are specialized packaging solutions that cater to branding and aesthetic needs, significantly influencing consumer perception and market competitiveness. Their cost is shaped by a range of factors, including material selection, printing techniques, design complexity, order quantities, and logistics. Businesses must navigate these variables to optimize their packaging budgets while meeting consumer expectations for quality and sustainability. As environmental concerns gain prominence, the choice of materials and production methods increasingly reflects a commitment to eco-friendly practices, further complicating the cost equation.

The selection of materials plays a pivotal role in the pricing of custom colored boxes, with options ranging from economical cardboard to high-end glass. Each material’s suitability and cost-effectiveness depend on the product’s positioning and the desired visual impact. Additionally, printing methods can significantly affect overall expenses, with digital printing often favored for smaller runs due to its flexibility, while offset printing remains popular for larger volumes despite higher initial costs. Design complexity also impacts production costs; intricate designs typically incur additional labor and processing time, leading to higher expenses.

Order quantities are another critical factor in determining cost, as larger orders often benefit from economies of scale, reducing the per-unit price. Conversely, small orders can result in higher individual costs, which may not align with budget constraints. Furthermore, logistics and shipping expenses add another layer of complexity to the pricing structure, necessitating careful planning to minimize overall expenditures.

As the demand for sustainable packaging grows, businesses face the challenge of balancing cost considerations with the implementation of eco-friendly materials and practices. Companies that adopt sustainable solutions not only meet regulatory and consumer expectations but also enhance their brand reputation. This ongoing shift towards sustainability underscores the importance of evaluating both the economic and environmental impacts of custom colored boxes in today’s packaging landscape.

Table of Contents

Factors Influencing Cost

The cost of custom colored boxes is determined by a variety of factors that can significantly impact both the upfront and long-term expenses associated with packaging design and production.

Material Selection

The choice of materials is one of the most critical factors influencing the cost of custom packaging. Common materials such as white cardboard, coated paper, art paper, and corrugated paper vary in price and suitability based on the product’s positioning and desired aesthetic appeal. High-end materials like glass or metal may enhance product value but come with higher costs, while more affordable options like paper or cardboard can help control expenses and align with sustainability goals. The overall look, texture, durability, and cost of the packaging are all directly impacted by material selection.

Printing Techniques

Different printing methods also contribute to packaging costs. For smaller runs, digital printing may offer a more cost-effective solution compared to traditional offset printing due to its flexibility and faster turnaround times. The choice of printing technique should consider both budget constraints and the desired quality of the final product, as well as the environmental impact of the printing process.

Design Complexity

The complexity of the packaging design significantly affects production costs. Intricate designs requiring multiple colors, embossing, or foil stamping can lead to higher expenses due to increased production time and additional processing steps. Simpler designs, on the other hand, tend to be more economical. By opting for minimalistic aesthetics with fewer colors, businesses can effectively reduce printing costs and production difficulties.

Order Quantity

The volume of boxes ordered plays a substantial role in determining the cost per unit. Larger orders benefit from economies of scale, allowing for reduced individual unit prices as setup and production costs are spread over more units. For instance, small orders may cost between $0.50 and $1.50 per unit, while larger orders can decrease to as low as $0.20 to $0.80 per unit. Balancing order quantities with actual needs is essential to avoid unnecessary storage costs associated with overordering.

Logistics and Shipping

Logistics and shipping costs are additional factors that influence the overall price of custom packaging. The size and weight of the packaged product can affect transportation costs, and optimizing box dimensions to fit the product can help reduce material waste and shipping expenses. Furthermore, indirect costs such as storage and environmental impact should be taken into account when evaluating the total cost of packaging solutions.

Craftsmanship Complexity

The “complexity of craftsmanship” is another significant determinant in the pricing of custom packaging. More sophisticated techniques that enhance the visual and tactile quality of the boxes may lead to increased setup time, labor, and scrap rates. Brands must balance the desire for high-quality aesthetics with budget considerations to ensure cost-effective packaging solutions that meet consumer expectations.

Cost Breakdown

The cost of custom colored boxes is influenced by various factors, making it essential for businesses to understand these elements to optimize their packaging budget.

1. Production Costs

Production costs play a significant role in determining the price of custom colored boxes. The complexity of the design, the selection of materials, and the required production techniques contribute to overall expenses. Unique designs often necessitate specialized tools and machinery, which can lead to higher costs due to increased development time and labor intensity. Furthermore, the manufacturing process is also affected by the chosen materials, with certain types like biodegradable options often being more expensive than conventional materials.

2. Shipping Costs

Shipping can significantly impact the final cost of custom packaging. The expenses associated with transporting these boxes can range from $1.8 to $420, depending on factors such as package weight, destination, and shipping service chosen. Businesses must account for these logistics costs when budgeting for custom boxes.

3. Material Costs

The choice of materials used in the creation of custom colored boxes is a crucial cost factor. For instance, the price of containerboard—a primary component in corrugated packaging—has experienced fluctuations, influencing overall pricing. Different materials incur varying costs, with plastic often being less expensive than paper, while glass packaging tends to be more costly due to its fragility. Sustainable packaging materials may also present higher price points, reflecting their production and environmental impact.

4. Quantity and Customization

The quantity of boxes ordered can significantly affect unit pricing. Generally, larger orders benefit from bulk pricing discounts, reducing the per-unit cost. However, customization adds another layer of complexity to the cost structure. Custom-designed boxes typically require additional design work and production time, making them pricier than standard options.

5. Efficiency Techniques

While not extensively covered in the collected information, employing efficiency techniques during the manufacturing and shipping processes can help control costs. Automation in production can enhance speed and quality while reducing labor costs, leading to lower overall expenditure for custom colored boxes. Adopting efficient logistics solutions can also minimize shipping costs and improve delivery times, ultimately benefiting the bottom line.

Economies of Scale

Economies of scale play a crucial role in the cost considerations of custom colored boxes. When businesses place larger orders, they often benefit from a reduction in per-unit costs due to the distribution of fixed costs over a greater number of units produced. This approach not only makes high-volume orders more budget-friendly in the long run but also enables suppliers to offer significant discounts for bulk orders, leading to substantial savings for businesses.

Impact on Pricing

The pricing structure for custom colored boxes is heavily influenced by order volume. Bulk orders typically experience lower per-unit costs because the setup expenses are shared across more prints. For instance, if a business opts for a high-volume order, the cost savings can be considerable, making it a financially sound decision, particularly for materials with long shelf lives that do not require frequent updates. Conversely, low-volume orders may have higher per-unit costs, but they provide flexibility for specialized products or limited editions, which can be beneficial for companies that need to respond quickly to market changes.

Sampling and Order Flexibility

The sampling process also varies significantly between high-volume and low-volume projects. High-volume orders often include free samples, allowing businesses to test the design and functionality before committing to mass production, thereby ensuring that the final product meets their specifications. In contrast, low-volume projects may involve creating a single sample for client approval, which enables adjustments before placing a larger order. This flexibility in sampling helps businesses align their custom packaging with branding and financial strategies while managing costs effectively.

Negotiation and Supplier Relationships

Building strong relationships with suppliers can further enhance cost efficiencies. By negotiating better pricing and exploring favorable terms, businesses can maximize their savings on custom colored boxes. Regularly reviewing and renegotiating contracts as business scales can also contribute to ongoing cost-effectiveness, ensuring that companies remain competitive in a dynamic market environment. Overall, leveraging economies of scale is a vital strategy for businesses looking to optimize their custom packaging solutions while maintaining quality and aesthetic appeal.

Sustainability Considerations

Sustainability has become a critical aspect of packaging design and manufacturing, particularly in the context of custom colored boxes. As consumers increasingly prioritize eco-friendly practices, companies are exploring sustainable materials and processes to minimize their environmental impact. The adoption of sustainable packaging solutions not only meets consumer demands but also enhances brand reputation and fosters loyalty among environmentally conscious shoppers.

Principles of Sustainable Packaging

The foundation of sustainable packaging lies in the principles of sustainable materials management. This approach aims to reduce environmental impacts by recovering and utilizing materials efficiently throughout the supply chain. Key strategies include the use of biodegradable materials, which are specifically designed to break down naturally over time, thereby reducing pollution and enriching the soil instead of contributing to landfill waste. Moreover, utilizing packaging made from 100% recycled or raw materials further minimizes environmental impacts.

Life Cycle Assessment (LCA)

To evaluate the sustainability of packaging options, businesses often employ Life Cycle Assessment (LCA). This method analyzes the environmental footprint of packaging from resource extraction to final disposal, allowing companies to identify the most sustainable practices. LCAs highlight the importance of prevention, reuse, recycling, recovery, and responsible disposal of packaging materials, with an emphasis on minimizing unnecessary material use and energy consumption.

The Role of Biodegradable Materials

Biodegradable materials play a pivotal role in the shift toward sustainable packaging. Unlike traditional plastics, which can take hundreds of years to decompose, biodegradable options, such as those made from organic substances, are designed to break down naturally, thereby significantly reducing pollution. These materials not only address environmental concerns but also align with the growing consumer preference for products that support conservation efforts.

Industry Initiatives

Major corporations are increasingly committing to sustainability goals, such as transitioning to 100% recyclable or compostable packaging. These initiatives resonate with consumers and reflect a broader movement within industries, particularly in the food and beverage sector, towards reducing plastic waste and enhancing sustainability. By setting quantifiable targets, companies contribute to positive environmental change while bolstering their brand image.

Challenges and Innovations

Despite the advantages of sustainable packaging, challenges remain in sourcing biodegradable materials and implementing eco-friendly practices at scale. However, ongoing innovations in biodegradable packaging technologies continue to enhance the feasibility of using sustainable materials across various industries. Companies must weigh the costs and benefits associated with these sustainable options, ensuring they maintain quality and safety while reducing their environmental footprint.

Case Studies

Environmental Impact Assessments

A crucial aspect of evaluating the cost considerations for custom colored boxes involves conducting Life Cycle Assessments (LCAs). These assessments are tailored to account for the specific environmental impacts of packaging materials and designs across their entire life span. However, it is essential to note that while LCAs can provide valuable insights, the results are often not suitable for regulated carbon accounting practices due to their broad and general nature, which may not capture unique operational specifics of individual brands. For example, companies may adopt different methodologies for assessing greenhouse gas emissions, as seen with the varying Global Warming Potential (GWP) horizons applied by different tools such as the GHG Protocols and the Environmental Paper Calculator.

Color Psychology and Branding

Research into the psychological effects of color on consumer behavior indicates that the color of packaging can significantly influence brand perception and purchasing decisions. A study conducted by Wei-Lun Chang and Hsieh-Liang Lin explored how consumers reacted to colored logos, revealing that black packaging is often associated with traits such as darkness, mystery, and sophistication. Such associations can enhance the brand’s appeal, but companies must consider how these perceptions align with their overall branding strategy and consumer expectations.

Cost versus Customization

The decision to invest in custom colored boxes must balance the added costs of complex branding elements against the expected benefits in consumer engagement and brand recognition. Factors such as materials makeup, printing methods, and graphics intricacy can contribute to increased costs, but they also provide an opportunity for brands to tell their stories effectively. For example, while the upfront costs for eco-friendly packaging solutions may be higher, they can attract eco-conscious consumers and potentially lead to reduced long-term environmental impacts, aligning with growing consumer preferences.

Supply Chain Considerations

Recent trends in the packaging industry illustrate the challenges presented by global supply chain disruptions and labor shortages. These issues have led to increased pricing for raw materials, impacting the overall cost structure for custom packaging solutions. E-commerce businesses, in particular, have felt the pinch, as they require significantly more corrugated packaging compared to traditional retail, amplifying demand pressures. Small e-commerce businesses, in particular, must navigate these increased costs while maintaining profitability, emphasizing the need for transparency with customers regarding pricing changes due to external factors.

Enhancing Customer Experience

The evolution of consumer expectations has led to a greater emphasis on personalized and aesthetically pleasing packaging. Studies show that personalized packaging can enhance brand perception, leading to increased customer satisfaction and loyalty. Additionally, the emotional responses evoked by color and typography in packaging design can guide consumer purchasing decisions, highlighting the importance of strategic choices in packaging design. As consumers seek more than just product functionality, the presentation and brand narrative conveyed through packaging becomes critical for competitive differentiation.