Clamshell vs. Two-Piece Boxes

This blog compares clamshell and two-piece boxes, analyzing their design, applications, cost, and environmental impact to help you choose the best option.

Summary

Clamshell and two-piece boxes are two distinct types of packaging solutions widely used in various industries, each serving different purposes and market needs. Clamshell boxes, made primarily from durable plastics, are characterized by their transparent design that enhances product visibility while providing robust protection. They are particularly favored in retail for items such as hardware, electronics, and cosmetics, where the ability to inspect products before purchase is crucial. In contrast, two-piece boxes, often referred to as rigid boxes, are constructed from thick paperboard and are designed for luxury items, providing a high-end aesthetic and structural integrity that appeals to premium markets.

The notable distinction between these packaging types lies in their design intent: clamshells prioritize functionality and protection, making them ideal for everyday retail applications, while two-piece boxes emphasize presentation and durability, appealing to high-end consumers. The choice between the two depends on various factors, including the specific product being packaged, its market positioning, and consumer preferences for aesthetics versus utility.

Despite their advantages, both packaging types face scrutiny over environmental concerns. Clamshell packaging is often criticized for its contribution to plastic waste, although innovations in eco-friendly materials are gradually addressing these issues. Conversely, two-piece boxes, while generally more sustainable, may not offer the same level of visibility as clamshells, presenting a trade-off between presentation and environmental impact.

In summary, the clamshell versus two-piece box debate reflects broader trends in packaging design, consumer preferences, and environmental considerations. As industries evolve, manufacturers are increasingly challenged to balance functionality, aesthetic appeal, and sustainability in their packaging solutions, shaping the future landscape of product presentation and protection.

Table of Contents

Design and Structure

Clamshell Boxes

Clamshell packaging is recognized for its distinctive design that combines functionality and aesthetic appeal. Constructed primarily from durable plastics, clamshells can be either stock shapes or custom-molded to snugly fit various products. This design not only enhances product visibility but also offers robust protection, making them ideal for a range of items including hardware, electronics, and cosmetics. The transparent nature of these boxes allows consumers to view the product inside while safeguarding it against damage and shoplifting, which is particularly beneficial in retail environments.

Features and Benefits

One of the standout features of clamshell packaging is its stackable design, which conserves vertical space and optimizes storage both in retail and warehousing contexts. The uniform shapes allow for efficient stacking and nesting when empty, minimizing storage needs and transportation costs. Furthermore, many clamshell designs incorporate snap closures, enabling customers to reuse the packaging for storage or organization of items, thus enhancing the product’s value and utility.

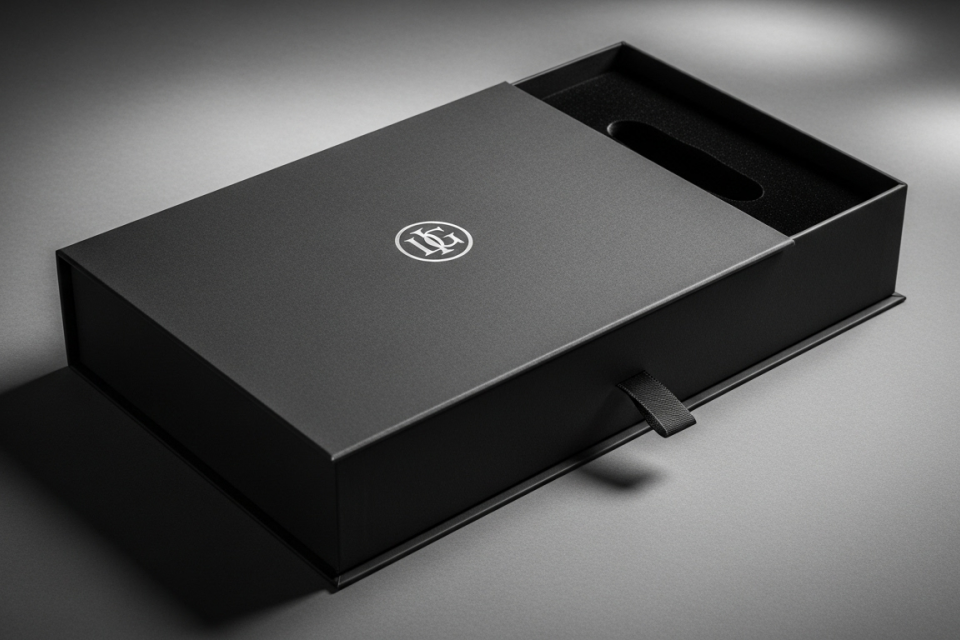

Two-Piece Boxes

In contrast, two-piece boxes, often referred to as rigid boxes, are crafted from dense, thick paperboard known as chipboard or greyboard. These boxes consist of a separate lid and base that fit together, providing a sturdy and non-collapsible structure that holds its shape well. This characteristic makes them particularly suitable for luxury items, such as cosmetics and electronics, where presentation and perceived value are crucial.

Structural Differences

While clamshell boxes are designed for visibility and protection, two-piece boxes prioritize a high-end feel and robustness. Rigid boxes can be wrapped in decorative materials to enhance their appeal, making them a popular choice for premium product packaging. The construction process involves cutting and scoring the paperboard, followed by applying stays to form the box structure, and finally wrapping it with decorative finishes.

Comparative Analysis

When comparing the design and structure of clamshell and two-piece boxes, it becomes clear that each serves different market needs. Clamshells excel in functionality and visibility, making them suitable for everyday retail applications, while two-piece boxes focus on luxury presentation and durability, appealing to high-end markets. The choice between the two often depends on the specific requirements of the product being packaged, including protection, aesthetic presentation, and brand positioning.

Advantages and Disadvantages

Clamshell packaging offers a range of advantages that make it a popular choice across various industries, particularly in retail and food packaging.

Advantages

Security and Protection

One of the primary benefits of clamshell packaging is its ability to provide security and protection for products. The design creates a tight seal around the product, minimizing risks of contamination, tampering, and damage during transportation and storage. This is particularly beneficial for items that could pose dangers to consumers, such as sharp tools, as it allows visibility while safeguarding against potential injuries.

Visibility and Presentation

Clamshells are designed to enhance product visibility, allowing consumers to inspect the product before purchasing. This feature is crucial for items where attributes such as color, texture, or freshness play a significant role in the buying decision. Furthermore, the packaging can be customized with high-quality graphics and transparent windows, improving product presentation and helping brands stand out in a crowded market.

Versatility and Customization

Clamshell packaging is highly versatile, available in various stock shapes and sizes, or customizable to fit specific products snugly. This adaptability makes clamshells suitable for packaging a wide array of items, including hardware, cosmetics, electronics, and fresh produce. The ability to tailor the packaging design also strengthens brand identity, allowing businesses to incorporate logos and product information effectively.

Disadvantages

Environmental Concerns

Despite their protective qualities, clamshell packaging has been criticized for its environmental impact, particularly due to the materials used and their contribution to plastic waste. Although innovations in eco-friendly materials are emerging, the perception of clamshells as environmentally unfriendly packaging persists among some consumers.

Complexity in Design for Large Items

For oversized items, clamshell boxes may require more complex construction, potentially using multiple pieces of board. This can lead to a bulkier footprint compared to two-piece boxes, which are often preferred for large prints and flat storage due to their more compact design.

Cost Considerations

Clamshell packaging can be more expensive to produce compared to simpler packaging types. The costs associated with customization and the materials required for durability can impact the overall pricing strategy for products, which may be a consideration for businesses operating on tight margins.

Applications

Clamshell packaging is widely utilized across various industries due to its versatility, convenience, and protective features. This section explores the primary applications of clamshells and their significance in packaging solutions.

Food Packaging

The food and beverage sector is the largest end-user of clamshell packaging, accounting for over 43% of the market share in 2023. Clamshells are particularly favored for packaging ready-to-eat meals, salads, sandwiches, and other perishable items. Their design not only enhances product visibility but also maintains freshness and safety during transport, catering to the growing demand for convenient food options. Moreover, the use of recyclable materials such as PET plastic in food clamshells aligns with sustainability trends and consumer preferences for eco-friendly packaging.

Healthcare and Pharmaceuticals

Clamshell packaging is also prevalent in the healthcare and pharmaceutical industries, where it is employed for packaging medical devices, dental products, and various pharmaceutical items. The durable construction of clamshells provides excellent protection against tampering and contamination, which is critical in maintaining product integrity and safety in these sensitive sectors.

Consumer Goods and Electronics

In addition to food and pharmaceuticals, clamshells serve as effective packaging solutions for consumer goods and electronic items. Their robust design and transparent features allow brands to showcase products while ensuring protection from dust, moisture, and physical impact. This is particularly beneficial for fragile items, providing a secure shipping and handling experience that enhances consumer trust and satisfaction.

Other Applications

Clamshell packaging extends its utility to various other applications, including personal care products, hardware items, and even some types of clothing. The inherent stackability and nestable design of clamshells optimize storage and display space in retail environments, making them a practical choice for both manufacturers and retailers.

Environmental Impact

The environmental impact of packaging is a growing concern among consumers, influencing their purchasing decisions. By 2025, 44 percent of consumers rated environmental impact as “extremely important” or “very important,” marking a return to pre-COVID-19 levels of awareness. Although this concern ranks lower than factors such as durability, it reflects a significant shift towards sustainable practices in packaging.

Benefits of Sustainable Materials

Utilizing sustainable materials, such as recycled paperboard and bioplastics, plays a crucial role in minimizing environmental impact. These materials are designed to reduce waste and promote a circular economy by encouraging reuse and recycling, which helps alleviate the burden on landfills. For instance, using rPET (recycled polyethylene terephthalate) in packaging has been shown to significantly decrease CO2 emissions, thus contributing to resource conservation.

Role of Clamshell Packaging

Clamshell boxes, often made from recyclable materials, offer several environmental advantages. Their design allows for efficient use of space, which reduces the carbon footprint during transportation. Moreover, clamshell packaging provides excellent protection for fragile items, minimizing damage and waste during transit. The inclusion of tamper-resistant features further ensures that products remain secure, promoting consumer trust in product safety.

Consumer Preferences and Corporate Responsibility

As consumer awareness of environmental issues rises, brands are increasingly prioritizing eco-friendly packaging solutions to meet these demands. Research indicates that the integration of recycled materials not only lowers energy consumption but also enhances corporate sustainability agendas, making businesses more appealing to eco-conscious consumers. Companies are exploring innovative options, such as glass and aluminum, which not only reduce waste but also improve their environmental image in the marketplace.

Technological Innovations

Advancements in technology, including machine learning, are facilitating the development of sustainable packaging materials. These technologies help optimize the use of plant-based materials and improve recycling efficiency, enabling companies to offer products that align with consumer values regarding environmental responsibility. Engaging with local governments and non-profit organizations further enhances these efforts, fostering a collaborative approach to reducing packaging waste.

Cost Comparison

The cost of clamshell packaging can vary significantly based on several factors, including the quantity ordered and whether the items are stock or custom-made. For instance, purchasing 1,000 clamshells may cost around $400, but buying in bulk, such as 10,000 units, can reduce the price to approximately $150 per 1,000. Manufacturers typically establish minimum order quantities, which can affect overall pricing. For example, if a minimum order of 3,000 units is required at a rate of $400 per thousand, the total cost would be $1,200.

When considering custom packaging solutions, tooling costs are an additional factor that influences overall expenses. These costs cover the creation of custom tools necessary for production, which can increase if the packaging design is unique or involves complex printing techniques. Furthermore, production costs are generally more economical with larger orders due to economies of scale, where the price per unit decreases as order volume increases.

Shipping costs must also be accounted for, as they can vary based on the size and weight of the packaging materials being transported. Although these costs can be minimal, they are important to consider when calculating the total expenditure on packaging solutions.

In terms of sustainability, the packaging industry is increasingly focusing on reducing the environmental impact of materials used. Sustainable packaging solutions often emphasize the use of recyclable and compostable materials, which may come at a premium but could lead to long-term savings through enhanced brand loyalty and consumer demand for eco-friendly products. Overall, while initial costs for clamshell packaging may seem higher compared to traditional two-piece boxes, the potential for cost savings through bulk purchasing and sustainable practices may offer a competitive advantage in the long run.

Consumer Preferences

Consumer preferences play a crucial role in shaping packaging design and materials, especially as awareness of environmental issues continues to rise. Research indicates that while environmental impact is significant, it is not the top priority for most consumers when making purchasing decisions. In 2025, approximately 44% of consumers ranked environmental impact as “extremely important” or “very important,” a return to pre-COVID-19 levels, yet this is significantly lower than the emphasis placed on price, quality, and convenience, which are ranked higher in importance by over 70% of respondents.

Importance of Sustainability

Despite environmental concerns being a lower priority overall, there is a notable segment of consumers who prioritize sustainable materials in packaging. As they seek products made from biodegradable or recyclable materials, brands are motivated to innovate and adapt their offerings to meet these preferences. This shift not only addresses the demand for responsible consumption but also reduces environmental impacts. Companies that proactively adopt sustainable practices and transparently communicate their efforts often enjoy a competitive advantage in the marketplace, fostering trust and loyalty among eco-conscious consumers.

Transparency in Sourcing

Transparency in packaging sourcing is becoming increasingly vital as consumers demand accountability. Brands that disclose the origins and production methods of their materials resonate with consumers who prioritize ethical and sustainable practices. Companies committed to sustainable forestry or using certified recycled materials enhance their credibility, aligning their values with those of their customers, which can significantly influence consumer loyalty.

Evolving Consumer Expectations

Consumers expect packaging to meet a comprehensive set of needs beyond sustainability alone. Factors such as durability, food safety, shelf life, and convenience are crucial in their purchasing decisions. As consumers become accustomed to high-quality products and convenient access, they are less likely to choose packaging that excels in sustainability at the expense of these other factors. Furthermore, the appearance of packaging has become less critical, likely due to the rise of online shopping, where the visual appeal is not as prominent during the purchasing process.

Variability by Product Category

The importance of specific factors varies by product category. For instance, brand recognition is particularly significant in sectors like beverages, pet food, and personal care, serving as a proxy for quality and price. Consequently, packaging companies must adopt a holistic approach, ensuring that their designs not only highlight sustainability but also fulfill other essential consumer preferences.