The Strategic Application of Custom Boxes Across Diverse Industries

Packaging, especially the custom box, serves as a critical interface between products and consumers and as an essential part of logistics chains.

Introduction

Packaging, especially the custom box, serves as a critical interface between products and consumers and as an essential part of logistics chains. Development from generic containers for highly specialized customized boxes underlines sophisticated understanding of science of material, engineering and market dynamics. This article explores a variety of boxes of boxes in various industries and explains how specific functional requirements determine the design of packaging and material selection.

The Varied Functional Demands for Boxes in Different Industries

The operational requirements of the industry largely determine the structural and material specifications of its packaging. Companies across sectors strategically use their own boxes to meet these unique challenges, ensure product integrity, brand coherence and logistics efficiency.

Retail Sector

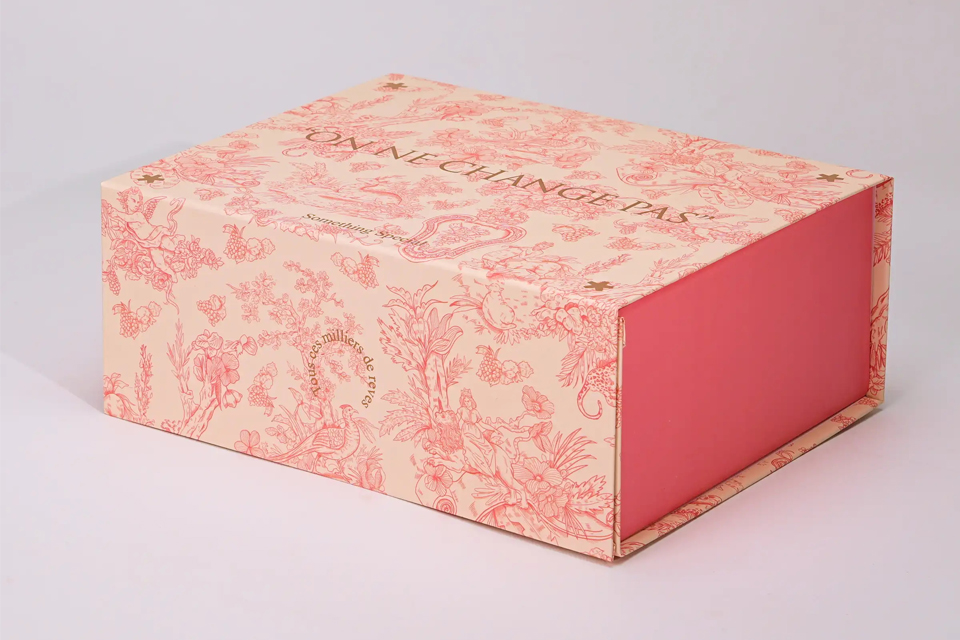

The retail environment requires packaging that protects not only but also sells the product. Retail boxes according to industry standards, often manifest themselves as folding cartons or premium rigid boxes, using sophisticated graphic design and structural ingenuity. These custom printed boxes increase the revisions of attraction and significantly contribute to the decision of the consumer, which acts as a primary touch point for the interaction of the brand in both physical stores and more and more, through the opening experience of the opening online.

Food and Beverage Sector

This sector places primary importance for food safety, protection and compliance. For their barrier properties, packaging materials such as specialized cardboard and corrugated paper boxes are selected, preventing contamination and maintaining freshness. The design often includes properties for temperature control, humidity resistance and handling evidence, ensuring that the product reaches the consumer in optimal state.

Electronics Sector

The electronic industry requires a packaging solution that offers excellent protection against physical shock, electrostatic discharge (ESD) and environmental factors such as humidity. Electronics packaging boxes often use multilayer corrugated boards, custom -made foam inserts and antistatic materials. The structural integrity of these boxes is decisive for the protection of fine and highly valuable components in complex global supply chains.

E-commerce Sector

Quick expansion of electronic trading has intensified religious and versatile transport solutions. Corrugated paper boxes are the basis, designed to withstand the strictness of multiple handling points and different transit conditions. In addition to mere protection, electronic trading packaging is increasingly perceived as an extension of the brand, while adapting to size, printing and internal organizations increases the experience of unpacking the customer and strengthens the brand loyalty.

Material Science and Structural Engineering in Custom Box Design

The efficiency of packaging boxes is fundamentally rooted in the principles of material and structural engineering. Selection of suitable substrates-from different stages of cardboard (eg solid bleached sulphate (SBS), clay reports coated (CCNB)) for various flutes in undulating fiber (eg e-fiction for printability, BC-button for strength)). Engineers then design the structure of the box, with respect to factors such as load capacity, crush resistance (ECT test – ECT, BURST – MULEN test) and protective internal fittings. For example, a box designed for heavy industrial parts will require a high wavy material with a double wall, while a luxury cosmetic item could use a rigid box made of thick cardboard laminated with special paper. This careful engineering ensures that their customized boxes provide optimal protection while coping with aesthetic and cost parameters.

Technological Integration in Modern Box Manufacturing and Utility

Recent technological advancements significantly enhance the capabilities and applications of custom boxes. Digital printing technology enables high -resolution and variable data printing directly to box substrates, allowing bulk adaptation and targeted marketing campaigns with minimal setting costs compared to traditional or flexographic printing. In addition, progress in spinning and automated mounting lines improve production speed and accuracy. In addition to production, the “Smart Packaging” solution appears and integrates technologies such as NFC (communication near the field) or QR codes into their own boxes. They allow consumers to access product information, verify authenticity, or engage in the interactive brand content and transform a box from a mere container into an interactive digital touch point.

Comparative Analysis of Box Types by Industrial Application

To illustrate the specific needs met by custom boxes across sectors, the following table outlines common applications:

| Industry | Common Box Types | Key Requirements | Material Focus |

|---|---|---|---|

| Retail | Folding Cartons, Rigid Boxes, Display Boxes | Visual Appeal, Brand Representation, Product Visibility, Structural Integrity | High-quality Paperboard, Specialty Papers, Clear Plastics |

| Food & Beverage | Paperboard (Coated/Uncoated), Corrugated Boxes | Food Safety, Freshness Preservation, Barrier Properties, Tamper Evidence | FDA-approved Materials, Grease/Moisture Resistant Coatings |

| Electronics | Corrugated Boxes, Rigid Boxes with Foam Inserts | Shock Absorption, ESD Protection, Durability, Security | Anti-static Materials, High-strength Corrugated, Cushioning |

| E-commerce | Corrugated Shipping Boxes, Mailer Boxes | Durability for Transit, Right-sizing, Unboxing Experience, Brand Reinforcement | Recycled/Recyclable Corrugated, Lightweight Options |

| Pharmaceutical | Temperature-controlled Boxes, Secure Cartons | Temperature Stability, Security, Compliance, Child-resistance | Insulated Materials, Tamper-evident Seals, Pharma-grade Board |

| Automotive | Heavy-duty Corrugated Boxes, Custom-fit Part Boxes | Strength for Heavy Parts, Oil/Grease Resistance, Stackability | High ECT Corrugated, Reinforced Designs, Coated Liners |

Critical Factors Influencing Custom Box Specification

The decision -making process for selecting or designing your own boxes includes a multilateral analysis of several critical factors:

- Product characteristics: the internal properties of the product – its dimensions, weight, fragility and material composition – are primary determinants. Fine objects require improved suspension, while irregularly shaped products may require inserts designed to custom or solutions.

- Logistics requirements: The intended transport and manipulation environment deeply affects the design of the box. Reflections include traffic mode (air, sea, soil), stacking height, storage conditions and number of touch points in the supplier chain. The box must maintain structural integrity according to these diverse tension.

- Brand communication and identity: Custom boxes are a powerful vehicle for sending a brand. The selection of materials, printing techniques (offset, flexography, digital), surface treatment (laminates, varnishes, relief) and overall design contributes to brand recognition and perceived value.

- Environmental liability and sustainability: for industries, the necessary packaging solutions are growing. This affects the selection of materials (eg recycled content, paper with FSC certification), suggestions that minimize waste (right size) and reflections on the end of life, such as recyclability or compostability.

Conclusion

Strategic deployment of custom boxes is necessary across the number of industries. From ensuring the safe transit of the goods in the electronic trading and electronics industry to increase the presence of the brand in retail and guaranteeing the integrity of the product in the food industry, boxes in various industries are designed to meet the exact functional, aesthetic and regulatory requirements. As technology and material science will continue to proceed, the sophistication and usefulness of their own boxes will undoubtedly spread, which further consolidates their role in the cornerstones of modern trade and logistics.