What Is Child-Resistant Packaging?

This blog covers child-resistant packaging, its life-saving origins, various types, and the ongoing challenge of balancing child safety with adult accessibility.

Summary

Child-resistant packaging (CRP) refers to specialized designs aimed at preventing young children from accessing hazardous substances while allowing adults to open them with relative ease. The importance of CRP stems from its effectiveness in reducing accidental poisonings among children, particularly those under five years of age, thereby playing a vital role in public health safety. Since the enactment of the Poison Prevention Packaging Act (PPPA) in 1970, CRP has been recognized as a significant factor in lowering child mortality and emergency care costs associated with accidental poisonings, making it one of the most successful public health interventions of the modern era.

The design of child-resistant packaging involves a variety of mechanisms, such as push-and-turn, squeeze-and-turn, snap-lock caps, and blister packs, all tailored to challenge young children’s capabilities while remaining functional for adults. Regulatory bodies like the Consumer Product Safety Commission (CPSC) in the United States enforce standards that mandate a minimum level of child resistance, with guidelines stipulating that at least 85% of children should be unable to open the packaging without assistance. These regulations ensure that products meet essential safety benchmarks, with compliance verified through rigorous testing procedures.

Despite its successes, child-resistant packaging is not without controversies and challenges. Critics point to the potential for designs to inadvertently complicate access for adults, particularly seniors or individuals with disabilities, raising concerns about inclusivity in product design. Furthermore, manufacturers must navigate a complex landscape of evolving regulations and compliance requirements, which can lead to increased costs and development delays. The ongoing balance between child safety, adult usability, and regulatory compliance remains a significant topic of discussion in the field of packaging design.

Looking towards the future, trends in child-resistant packaging are influenced by advances in technology, sustainability initiatives, and user-centered design. Innovations such as smart technology integration, eco-friendly materials, and enhanced testing methodologies aim to address the complexities of CRP while ensuring that it meets the diverse needs of users across all demographics. As the packaging industry evolves, the commitment to safeguarding children while providing accessible solutions for adults will continue to shape the landscape of child-resistant packaging.

Table of Contents

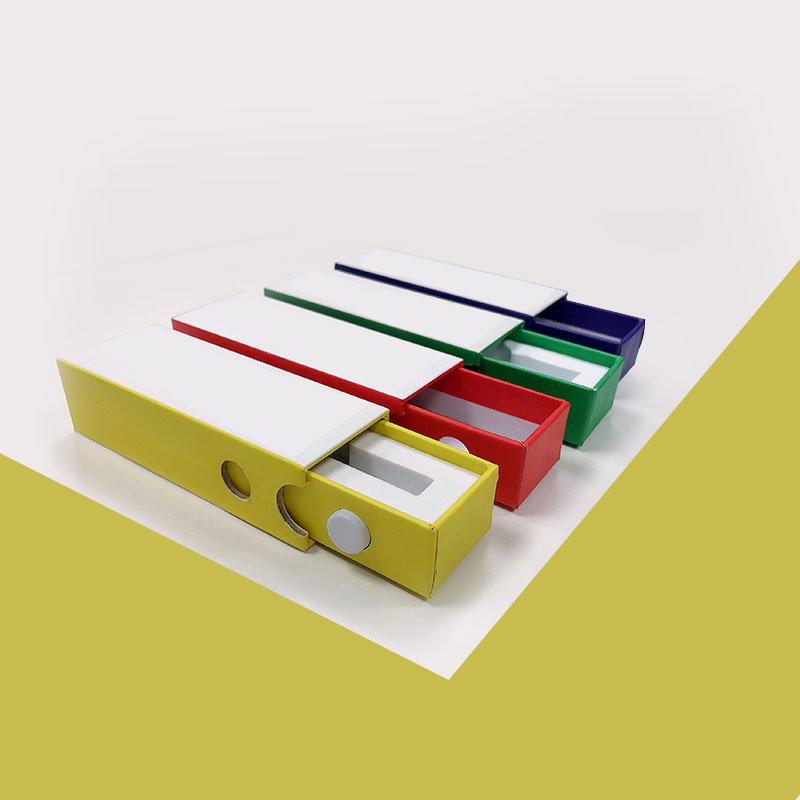

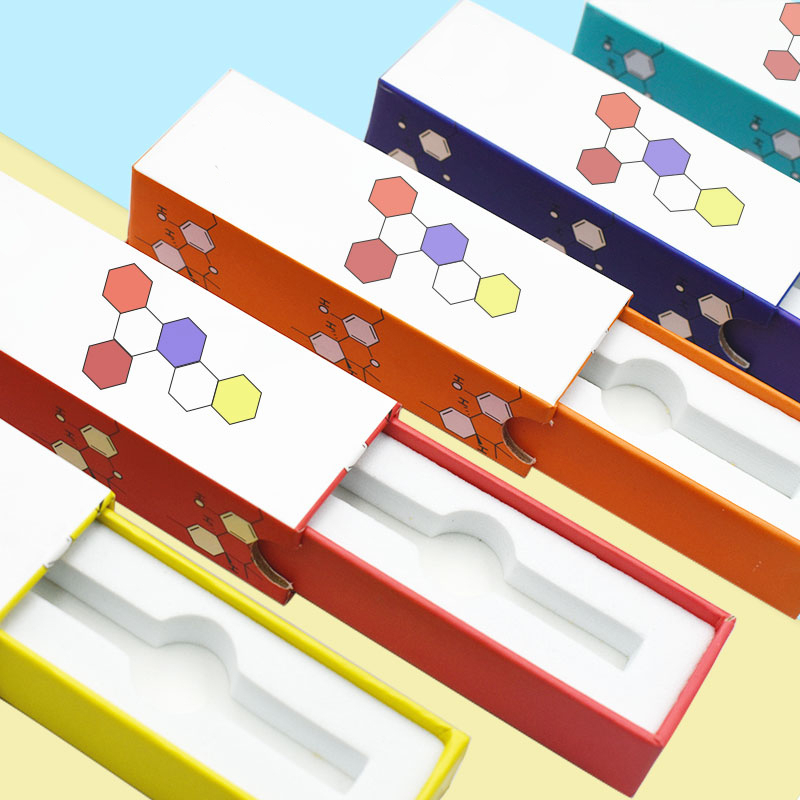

Types of Child-Resistant Packaging

Child-resistant packaging (CRP) encompasses a variety of designs aimed at preventing children from accessing hazardous materials while allowing adults to open them easily.

Mechanisms of Child-Resistant Closures

Push-and-Turn Closures

Push-and-turn closures require the user to push down while twisting the cap, making it difficult for young children to manipulate. These are commonly used on pharmaceutical containers, mouthwash bottles, and various household products.

Squeeze-and-Turn Closures

Similar to push-and-turn designs, squeeze-and-turn closures necessitate a combination of squeezing the sides and twisting the cap to open the container. This extra layer of complexity enhances child resistance and is frequently found on liquid medications and household chemicals.

Snap-Lock Caps

Snap-lock caps employ a locking mechanism that requires a specific sequence of motions—often involving pressing, twisting, or lifting—to unlock the cap. They are typically found on products such as aerosol sprays and antifreeze.

Flip-Top Closures

These closures involve a mechanism that demands a combination of pressing down and flipping a cap to open. This design is intentionally complicated for children while remaining manageable for adults.

Innovative Designs in Child-Resistant Packaging

Blister Packs

Blister packs with peel-push designs incorporate an additional step, making it more challenging for children to open while remaining accessible to adults. The peeling action acts as a deterrent against unauthorized access.

Child-Resistant Zippers

Child-resistant zipper pouches feature an interior tab that must be lifted before the package can be zipped open. This design is particularly useful for flexible packaging solutions, such as those used for cannabis products and snacks.

Dual-Function Closures

Some child-resistant designs integrate both child-resistant features and tamper-evident seals. This dual-functionality reduces packaging complexity while enhancing overall product security.

Additional Features for Safety and Usability

Effective child-resistant packaging also employs strategies to improve adult usability without sacrificing safety. Complex opening mechanisms, unintuitive instructions, and ergonomic designs are vital components. For instance, materials with enhanced grip and more intuitive opening methods facilitate adult access while remaining difficult for children to operate.

Regulations and Standards

Child-resistant packaging (CRP) is subject to various regulations and standards designed to ensure safety and prevent accidental access by children. The most recognized standards include ISO 8317 and ASTM D3475, which outline performance requirements and testing procedures for reclosable packages intended to be child-resistant. These standards establish a framework for manufacturers to evaluate the effectiveness of their closures and promote compliance with child safety measures globally.

International Standards

ISO 8317 serves as an international benchmark for child-resistant packaging, ensuring that products adhere to rigorous testing protocols that validate their safety features. ASTM International, previously known as the American Society for Testing and Materials, has also developed critical standards, including ASTM F3159, which defines test methods for assessing the child resistance of packaging. These international standards align closely with U.S. regulations but may vary across jurisdictions.

U.S. Regulations

In the United States, the Consumer Product Safety Commission (CPSC) oversees compliance with the Poison Prevention Packaging Act (PPPA) of 1970, which mandates that certain household substances be packaged in child-resistant containers. Additionally, the Food and Drug Administration (FDA) sets forth specific regulations for pharmaceutical and over-the-counter medications, emphasizing the need for packaging that protects children from potential harm. Manufacturers must remain vigilant about regulatory changes to ensure that their packaging meets or exceeds these safety requirements.

Certification and Compliance

Products that successfully meet established child-resistant packaging standards are often awarded certification marks, indicating compliance to consumers and regulatory bodies. This certification process involves rigorous testing by accredited laboratories to verify that the packaging adheres to relevant safety standards. Non-compliance can lead to legal consequences, as manufacturers are required to certify that their packaging meets the specified effectiveness and durability standards outlined in federal regulations.

Challenges in Compliance

Manufacturers face several challenges in the testing and compliance process for child-resistant packaging. Design iterations may be necessary if initial packaging does not pass testing, leading to additional costs and extended timelines for product launches. Furthermore, regulatory changes can prompt manufacturers to modify their packaging designs to stay compliant with new standards.

Global Perspective

While U.S. regulations set a significant precedent for child-resistant packaging, international standards also play a crucial role. The European Union has implemented its own standards, such as BS EN ISO 13127:2012 and BS EN ISO 8317:2004, which maintain similar performance thresholds to ensure safety across borders. Furthermore, state-level regulations may exceed federal minimums, especially in specialized markets like cannabis, necessitating additional packaging certifications. As manufacturers navigate these diverse regulatory landscapes, they are encouraged to adopt higher standards of social responsibility to enhance product safety for consumers, particularly children.

Effectiveness

Child-resistant packaging has been established as a critical element in preventing accidental poisonings among children, particularly those under the age of five. The effectiveness of such packaging is supported by regulatory standards, which mandate a minimum level of child-resistance; specifically, at least 85% effectiveness without demonstration and at least 80% after demonstration of proper use. This effectiveness is crucial as accidental ingestions continue to pose significant health risks, with over 66,000 reported emergency department visits for poisoning among children under five in 2020 alone.

Historical Context and Impact

Since the implementation of the Poison Prevention Packaging Act (PPPA) in 1970, child-resistant packaging has played a vital role in reducing child poisoning incidents. Research indicates that the introduction of child-resistant packaging requirements has led to significant decreases in both child mortality and emergency care costs associated with accidental poisonings. The approach is viewed as one of the most successful public health interventions of the modern era, demonstrating measurable safety improvements over the decades.

Testing and Standards

The efficacy of child-resistant packaging is verified through rigorous testing protocols. ASTM D3475 standards guide the evaluation process, which includes testing across diverse child populations to ensure realistic conditions. Each child participant tests multiple packaging designs, with results indicating that the design must successfully resist access by children while still being usable by adults, particularly those aged 50 to 70 who may face challenges due to age-related dexterity loss. It is recommended that 90% of adult participants can successfully open a package within specified time limits, maintaining the balance between safety and usability.

Economic Considerations

The economic impact of child-resistant packaging is also significant. Preventing poisonings not only safeguards children but also results in substantial healthcare cost savings that far exceed the expenses associated with implementing such packaging solutions. This economic rationale further strengthens the case for widespread adoption of child-resistant packaging across various consumer products, particularly those that contain hazardous substances.

Comprehensive Safety Approach

It is essential to recognize that child-resistant packaging is part of a broader strategy for ensuring child safety, which includes proper storage, adult supervision, and community education. While packaging serves as a critical last line of defense, it cannot eliminate all risks associated with accidental ingestion; therefore, it must be integrated into a multi-faceted approach to child safety.

Design Considerations

Designing child-resistant packaging (CRP) involves careful consideration of various factors to effectively balance safety for children and accessibility for adults. The design process is multi-faceted, requiring a comprehensive understanding of both the target audience and the products being packaged.

Understanding the Target Audience

The primary target audience for child-resistant packaging includes children under five years old and adults. Designers must analyze the developmental stages of children, particularly their cognitive and motor skill abilities, to create packaging that poses a challenge for young children while remaining manageable for adults, including those with disabilities.

Children

Children’s abilities to understand and manipulate objects differ significantly with age. Therefore, packaging must be designed to be difficult for young children to open, taking into account their limited dexterity and understanding of mechanisms.

Adults

Adults vary widely in their dexterity and cognitive capabilities, necessitating designs that can be easily operated by the majority of the adult population. This includes accommodating seniors who may have diminished physical capabilities.

Key Design Elements

Effective CRP incorporates specific design elements to deter children from accessing harmful substances while ensuring usability for adults. Squeeze-and-turn caps: Users must apply pressure while simultaneously rotating the cap, requiring a level of coordination that typically exceeds children’s capabilities. Push-and-turn mechanisms: These require users to push down on the cap before turning it, creating a similar challenge for children. Two-action mechanisms: Many CRP designs involve dual actions to open, such as ‘push and twist’ configurations, complicating access for children without alienating seniors.

Prototyping and Testing

The design process typically progresses through stages of prototyping and testing against established standards and regulations. This includes adhering to guidelines from organizations such as the Consumer Product Safety Commission (CPSC), which mandates that 80% of children must be unable to open the packaging, while 90% of adults without disabilities should be able to do so.

Sustainability Considerations

As environmental concerns grow, the design of CRP is also evolving. New approaches focus on mono-material designs that maintain child resistance while improving recyclability and end-of-life disposal options. This reflects a broader trend towards sustainable packaging practices across the industry, ensuring that safety does not come at the expense of environmental responsibility.

By carefully considering these design elements and audience needs, manufacturers can create effective child-resistant packaging that protects children while remaining functional for adults.

Challenges and Limitations

Child-resistant packaging (CRP) design faces a range of challenges and limitations that complicate the balance between safety and usability.

Balancing Safety and Usability

The fundamental challenge in CRP design lies in balancing the competing requirements of ensuring safety for children while maintaining usability for adults. Effective CRP must present a significant challenge for young children, specifically those under five years of age, while being accessible for adults without excessive difficulty. This delicate equilibrium is particularly difficult to achieve, as overly complex designs can lead to user confusion, where adults struggle to open the packaging due to complicated mechanisms.

Accessibility for Individuals with Disabilities

Despite the safety benefits of CRP, these closures can unintentionally create accessibility challenges for individuals with disabilities. As awareness of disability issues continues to grow, there is an urgent need for products that can accommodate diverse user needs, yet many designs still fail to address these concerns adequately.

Regulatory Compliance and Testing

Regulatory compliance remains a significant challenge for manufacturers, who must navigate a complex landscape of requirements set by bodies such as the United States Consumer Product Safety Commission (CPSC) and the Environmental Protection Agency (EPA). These regulations are crucial for ensuring child safety but can complicate the design process, requiring ongoing adjustments to meet evolving standards. Additionally, testing protocols can be costly and time-consuming, which may delay product launches and increase development costs.

The Impact of User Skills and Strength Variability

The variability in children’s physical abilities adds another layer of complexity. Children possess differing strengths and manipulative skills, which can affect their ability to open packaging. This inconsistency necessitates designs that are strong enough to deter children while remaining accessible to adults, including those with diminished dexterity due to age or disability. As the population ages and more individuals retain their independence longer, the relevance of current testing protocols may also need reevaluation.

Counterfeit Products and Safety Risks

The presence of counterfeit products further complicates the landscape of CRP. Manufacturers of fraudulent medicines often disregard safety regulations, leaving consumers vulnerable to unsafe packaging that lacks effective child resistance. The implementation of regulations such as the European Union’s Falsified Medicines Directive (FMD) seeks to address these issues, but the adaptation of packaging to meet these standards is still ongoing, highlighting the persistent risks in the market.

Future Trends

The future of child-resistant packaging is characterized by rapid advancements in technology, sustainability, and user-centered design. As the demand for safer and more functional packaging solutions continues to grow, innovations are being driven by both regulatory changes and consumer expectations.

Smart Technology Integration

One of the most significant trends in child-resistant packaging is the integration of smart technologies. Innovations such as biometric features, including fingerprint authentication, are enhancing the security of packaging, particularly for medications and hazardous household items. These smart solutions not only provide mechanical protection but also digital security, allowing only authorized users access to the contents. Additionally, sensor-based packaging is being developed to detect when a child attempts to open a product, activating alarms or sending notifications to adults’ mobile devices.

Sustainability Initiatives

Sustainability is becoming a critical focus in the development of child-resistant packaging. As environmental concerns rise, manufacturers are exploring eco-friendly materials and designs that reduce plastic usage without compromising safety. Innovations like recyclable pouches, such as those developed by Fresh-Lock®, significantly minimize plastic waste while maintaining child-resistant properties. The move towards mono-material designs also supports better recycling capabilities, aligning with global sustainability goals and the shift towards a circular economy.

Evolving Regulatory Standards

As regulatory frameworks evolve, child-resistant packaging requirements are expanding to cover new product categories. This evolution is anticipated to refine testing standards and enforcement mechanisms, with a focus on harmonizing international safety standards. Ongoing research may lead to more intuitive child-resistant mechanisms that balance safety and convenience, catering to both children and aging populations who may struggle with traditional packaging.

Advances in User Testing

To ensure effectiveness, new testing methodologies are being implemented that consider diverse user demographics, including older adults. Adult testing protocols require that a significant majority of participants successfully open and close packages, maintaining child-resistant properties. This focus on usability for all age groups is essential as populations age and require access to necessary medications without compromising safety for children.

Future Innovations

Emerging technologies, such as visual distraction methods and bioactive packaging, are also on the horizon, promising to enhance both safety and product preservation. These innovations are being designed to challenge children’s ability to open packages while ensuring that seniors can still access critical products easily. As packaging manufacturers continue to adapt and innovate, the future of child-resistant packaging looks to be more dynamic, user-friendly, and environmentally conscious than ever before.