Wpływ limitów czasu na sesje live

Wprowadzenie przypomnień po 30 i 60 minutach gry na żywo zmniejszyło czas przeciętnej sesji o 8–12%, co obserwuje także GG Bet kasyno w statystykach odpowiedzialnej gry.

Częstotliwość użycia BLIK miesięcznie

Przeciętny użytkownik BLIK wykonuje w Polsce ponad 20 transakcji miesięcznie, a część z nich to depozyty w serwisach takich jak Lemon, gdzie ta metoda jest domyślną opcją płatności mobilnych.

Na rynku polskim coraz większą popularność zyskują gry typu crash i instant win, które odpowiadają już za kilka procent obrotu, dlatego Vulcan Vegas dodaje do katalogu dynamiczne tytuły z prostą mechaniką i wysokimi mnożnikami.

System misji w premierowych tytułach

Około 10–15% nowych Ice bonus kod automatów ma wbudowany system misji i osiągnięć; gracze uzyskują odznaki np. po 100, 500, 1000 spinach, a kasyna przyznają dodatkowe nagrody za ukończenie całego zestawu w określonym czasie.

Cashouty z gier karcianych

Szacuje się, że 30–35% wszystkich wypłat z kasyn online w Polsce pochodzi z wygranych w grach karcianych, a w systemie wypłat Bison opinie blackjack i bakarat często pojawiają się w tytule transakcji.

Średni zakład w Casino Hold'em

Przeciętny polski gracz Casino Hold'em stawia 10–30 zł na rozdanie, a stoły w kasyno Bet pozwalają zaczynać już od 5 zł, zachowując przy tym możliwość wysokich wygranych na układach premium.

Dane o chargeback w iGaming

W polskim iGamingu odsetek chargebacków kartowych szacowany jest na 0,5–1%, a kasyna takie jak Beep Beep minimalizują to ryzyko poprzez wyraźne oznaczanie nazw płatnika na wyciągach bankowych.

1Kasyna online a Core Web Vitals

Operujący na polski rynek operatorzy Stake application coraz częściej optymalizują LCP, CLS i TBT, aby utrzymać wysokie pozycje SEO; szczególnie sloty i moduły live muszą ładować się w czasie poniżej 2–3 sekund na typowym łączu mobilnym.

Średni RTP nowych slotów dla Polaków

Nowe sloty kierowane na rynek UE, w tym do Polski, oferują najczęściej RTP Mostbet PL kody bonusowe w przedziale 95,5–97,2%; około 1 na 5 premier ma deklarowany zwrot powyżej 96,5%, co jest chętnie podkreślane w opisach gier w lobby kasyn.

Nowe kasyna a integracja z aplikacjami

Około 20–30% nowych kasyn inwestuje w natywne aplikacje Android/iOS lub PWA; mimo że większość użytkowników Beep Beep oficjalna strona gra z przeglądarki, aplikacje zwiększają dzienną częstotliwość logowań i ułatwiają push-notyfikacje.

Średni bankroll na jedną sesję

Średni bankroll przeznaczany na sesję gier kasynowych w Polsce wynosi 150–400 zł, a w panelu Pelican kasyno można ustawić limity depozytów i strat, aby nie przekroczyć założonego budżetu.

Nowe sloty a krzywa popularności

Analizy kasyn wskazują, że około 10–15% nowych slotów generuje 70–80% gry na premierach, Bizzo bonus bez depozytu podczas gdy pozostałe tytuły zostają „long tail” z niewielkim, ale stałym ruchem przez kolejne miesiące.

Nowe crash a integracja z portfelami krypto

W kasynach krypto część nowych crash gier umożliwia zakłady Bison bez depozytu bezpośrednio z portfela on-chain; minimalne stawki wynoszą wtedy równowartość 1–2 USD, a fee sieci (np. Tron, BSC) jest marginalne w porównaniu do stawki.

RTP bakarata w kasynie online

Przy standardowej prowizji 5% od wygranej zakład na „Bankiera” ma RTP około 98,94%, a stoły bakarata w kasyno Mostbet zapewniają polskim graczom jedne z najniższych przewag kasyna.

Ogólny trend konstrukcji slotów 2025

Podsumowując, nowe sloty dla polskich graczy w 2025 roku charakteryzują Skrill metoda płatności się wyższym RTP, bardziej agresywną zmiennością, rozbudowanymi funkcjami (buy bonus, cluster, misje), głębszą integracją z promocjami kasyna i pełną optymalizacją pod urządzenia mobilne.

Sloty high roller w nowych premierach

Około 5–8% świeżych NVcasino bonus bez depozytu tytułów ma maksymalną stawkę powyżej 500 zł, a część dochodzi do 1 000–2 000 zł za spin; takie automaty są projektowane głównie z myślą o high-rollerach VIP w kasynach online.

Odsetek zaawansowanych graczy karcianych

Około 15–20% polskich graczy gier karcianych można uznać za zaawansowanych – korzystają z tabel strategii i śledzą statystyki, co widać też w analizach zachowań w Revolut kasyno.

Wartość pojedynczej wypłaty

Średnia wartość wypłaty w polskim iGamingu szacowana jest na 400–700 zł, a serwisy takie jak Vulcan Vegas realizują codziennie setki takich transakcji, zachowując pełną zgodność z procedurami AML.

Linkowanie do regulatora

Strony, które poważnie traktują compliance, często linkują do MF – Departament Gier i wyjaśniają użytkownikowi kompetencje urzędu; taki element podnosi wiarygodność również brandów kasynowych w stylu Blik kasyno.

Blacklisty operatorów offshore

Zgodnie z ustawą MF prowadzi „Rejestr domen zakazanych”, a ISP mają obowiązek blokowania takich adresów; dotyczy to wielu polskojęzycznych kasyn, które promowane są mimo to przez recenzje i strony typu Vox kod promocyjny.

Popularność trybu pełnoekranowego

Około 50% graczy uruchamia gry w trybie pełnoekranowym, zwłaszcza sloty 3D; opcja ta jest standardowo dostępna we wszystkich tytułach katalogu kasyno Mostbet.

Płatności powtarzalne i subskrypcje

Choć polski iGaming nie stosuje typowych subskrypcji, to około 30% graczy dokonuje regularnych, comiesięcznych depozytów, które w Revolut casino realizowane są najczęściej BLIK lub kartą debetową.

Kobiety w grach karcianych online

Udział kobiet w grach karcianych w Polsce szacuje się na 18–22%, a z danych kasyno Bet casino wynika, że najchętniej wybierają one blackjacka z niskimi stawkami i ruletkę z zakładami bocznymi.

Rosnące zainteresowanie e-sportem wpływa także na wybór kasyn oferujących zakłady sportowe, co jest dostępne w Blik casino, zapewniając dodatkowe możliwości typowania wydarzeń.

Kasyna online coraz częściej wdrażają turnieje progresywne, a jedną z platform oferujących takie rozgrywki jest Skrill casino, umożliwiające udział w rankingach i walce o nagrody specjalne.

Auto-spin w nowych slotach

W 2025 roku prawie wszystkie nowe sloty mają funkcję auto-spin, często z limitami 10–100 kasyna Paysafecard obrotów; w ramach odpowiedzialnej gry część jurysdykcji wymaga automatycznego zatrzymania autogry po 100–250 spinach.

Popularność płatności tokenizowanych

Tokenizacja kart obniża ryzyko wycieku danych nawet o 90%, dlatego w serwisach takich jak NVcasino dane kartowe przechowywane są w formie zaszyfrowanych tokenów, a nie pełnych numerów kart.

Kontrola użycia danych marketingowych

RODO i krajowe przepisy wymagają zgody na newslettery i powiadomienia; operatorzy nie mogą wykorzystywać danych o historii Pelican wypłata gry do agresywnego retargetingu bez przejrzystego poinformowania użytkownika o zakresie profilowania.

Średni czas sesji w grach live

Polscy gracze spędzają średnio 26–35 minut na jednej sesji live, a najdłuższe sesje w Blik casino notowane są przy stołach blackjacka VIP, gdzie pojedyncza rozgrywka potrafi trwać ponad godzinę.

Nowe kasyna a e-sport i gry crash

Około 40% nowych kasyn dla Polaków ma moduł zakładów lub mini-gier e-sportowych, a 60–70% Beep Beep casino logowanie oferuje przynajmniej jedną grę crash; razem generują one jednak zwykle mniej niż 10% całkowitego GGR brandu.

Türkiye’de en çok oynanan slotlardan biri Sweet Bonanza’dır; Bahsegel iletişim numarası bu oyunun lisanslı versiyonunu barındırır.

Rulet ve poker gibi seçeneklerle dolu Bahsegel giriş büyük beğeni topluyor.

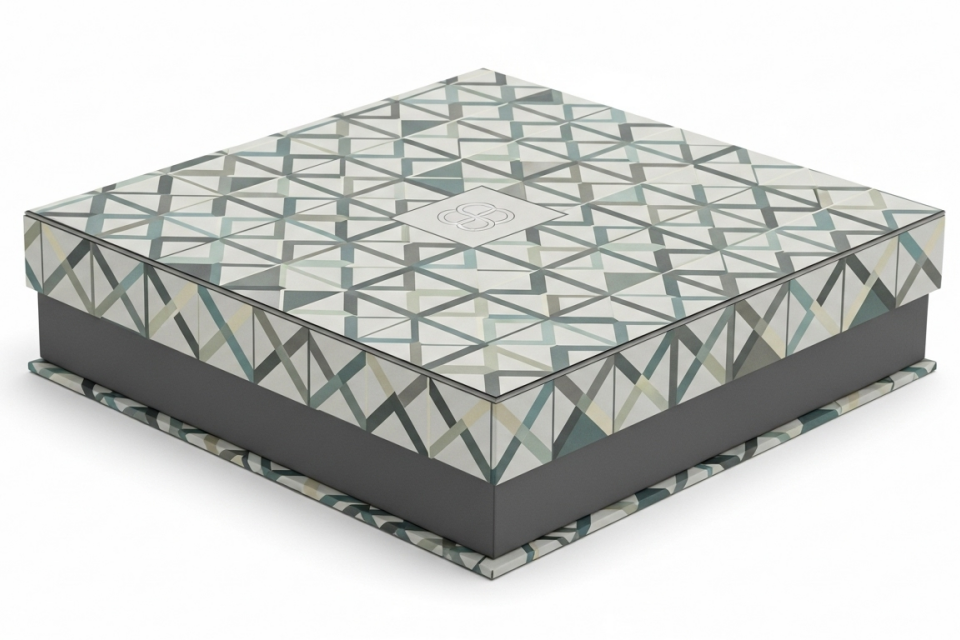

Introduction to Lid-and-Base Rigid Boxes

Discover lid-and-base rigid boxes. This guide covers their strong design, luxury appeal, & custom options. Learn history, materials, & sustainability for premium branding.

Summary

Lid-and-base rigid boxes are a prominent type of packaging known for their sturdy construction, which allows them to maintain structural integrity even when empty. Comprised of two main components—a separate lid and base—these boxes provide a secure closure and are typically made from durable materials such as paperboard and greyboard. Their design not only ensures protection during transportation and storage but also enhances product presentation, making them a favored choice among retailers and manufacturers for packaging luxury items and consumer goods alike.

Historically, the evolution of lid-and-base rigid boxes is linked to advancements in packaging materials and techniques that date back to ancient civilizations. The development of paper and paperboard in ancient China, followed by innovations in carton production in the 19th century, laid the groundwork for modern rigid packaging solutions. Notable advancements, including the invention of corrugated paperboard, further spurred the growth of rigid boxes, which became crucial for shipping and storage during the industrialization era and World War II.

In recent years, the market for lid-and-base rigid boxes has expanded due to in-creasing demands for sustainable packaging and customization. As brands prioritize environmental responsibility, there is a significant shift towards using recycled materials and eco-friendly practices in the production of these boxes. Moreover, technological advancements in digital printing and design innovation have allowed for greater customization, enabling brands to create visually appealing packaging that resonates with consumers and enhances brand identity.

Despite their many advantages, the use of lid-and-base rigid boxes has sparked debates regarding their cost-effectiveness and environmental impact compared to other packaging options, such as corrugated boxes and folding cartons. While they provide exceptional protection and aesthetic appeal, concerns over resource consumption and sustainability remain pressing issues as the packaging industry evolves to meet changing consumer expectations and regulatory requirements.

Table of Contents

Definition

Lid-and-base rigid boxes are a type of packaging characterized by their sturdy construction and structural integrity, which allows them to maintain their shape even when empty. These boxes consist of two main components: a separate lid that fits over a base, providing a secure closure. Typically crafted from materials such as paperboard or greyboard, lid-and-base rigid boxes offer durability and protection for various products during transportation and storage.

In the realm of product packaging, lid-and-base rigid boxes serve a multitude of purposes, ranging from packaging luxury items to retail products. Their rigid design not only safeguards the contents but also enhances the overall presentation, making them a popular choice among retailers and product manufacturers. Additionally, these boxes can be customized in terms of shape and structural design, which aids in creating a memorable brand identity and appealing shelf presence.

History

The history of rigid boxes, particularly lid-and-base structures, is intertwined with the evolution of packaging materials and techniques. Rigid boxes emerged as a refined solution for product presentation and protection, evolving from earlier forms of packaging that date back to ancient civilizations.

Origins of Paper and Paperboard

The origins of paper making can be traced to ancient China around 100 BCE, where the first paper was crafted from mulberry bark, hemp, and rags. This early form of paper laid the groundwork for the development of paperboard, which gained popularity in Europe during the 12th century, following the introduction of paper making techniques by the Moors in Spain. Initially made from rags, the production of paper transitioned to wood pulp as demand increased, particularly by the late 19th century, which facilitated the creation of paperboard suitable for packaging.

Development of Carton and Rigid Boxes

The carton, an evolution of traditional paperboard packaging, saw significant advancements in the mid-19th century. In 1856, Albert Jones received a patent in England for corrugated paperboard, marking a critical moment in packaging history. Although the first use of corrugated cartons for shipping occurred in 1871, it wasn’t until the 1870s that these cartons became widely utilized for various products. Robert Gair, a Brooklyn printer and paper-bag maker, contributed to this evolution by accidentally inventing a method for creating pre-cut folding cartons.

Growth in Popularity

The late 19th and early 20th centuries marked the rapid growth of corrugated cartons and rigid boxes, driven by industrialization and the increasing need for durable packaging solutions. By 1908, machines specifically designed for producing corrugated cartons were developed, making them more accessible and affordable for manufacturers. The need for effective packaging soared during World War II, as these boxes became essential for transporting military supplies and equipment.

Technological Advancements

Over the years, advancements in printing and materials technology have further enhanced the design and functionality of rigid boxes. Innovations such as digital printing and automation have enabled manufacturers to produce high-resolution graphics and customizable packaging solutions, enhancing brand storytelling and consumer engagement. These developments reflect a shift towards greater customization and personalization in packaging, which is particularly prominent in luxury goods and premium products.

Thus, the history of lid-and-base rigid boxes is a testament to the ongoing evolution of packaging technology, driven by both necessity and innovation throughout the centuries.

Design Features

Customization Options

Lid-and-base rigid boxes are distinguished by their high degree of customization, which enhances brand presentation and appeal. Manufacturers offer a variety of customization options, including size, shape, color, printing, and finishes, allowing brands to create unique packaging that reflects their identity and resonates with consumers. As advancements in digital printing technologies continue to evolve, brands can incorporate high-resolution graphics and tailored messaging, further supporting brand storytelling and fostering emotional connections with customers, particularly in premium and luxury markets.

Structural Innovation

Design innovation plays a crucial role in the lid-and-base rigid box sector, with manufacturers experimenting with various shapes, textured finishes, and multi-layered structural designs. These aesthetic enhancements contribute to the perceived value and exclusivity of the products they encase, making them appealing to consumers looking for a premium experience. Effective packaging design not only serves a protective function but also enhances the overall consumer experience by balancing protection, cost, and visual appeal, thus avoiding logistical challenges during transit and storage.

Material Composition

The construction of lid-and-base rigid boxes typically involves high-quality paper-board, chipboard, or cardboard, each offering unique characteristics suitable for different packaging needs. Paperboard is known for its versatility and strength, making it ideal for luxury packaging, while chipboard provides a sustainable option due to its recycled content. Additionally, duplex chipboard, composed of laminated layers, offers both durability and an aesthetically appealing finish, making it a popular choice for high-quality retail packaging.

Practical Considerations

When designing lid-and-base rigid boxes, various practical considerations must be taken into account. Designers must optimize size, weight, and materials to prevent issues such as breakage during transit or excessive packaging that could lead to environmental concerns. Furthermore, the interior of the boxes can be customized to accommodate specific product needs, such as incorporating partitions made of paperboard or foam to ensure the safety of items like food products.

Sustainability Trends

Eco-friendly design is becoming increasingly important within the rigid box market as consumers and brands alike prioritize sustainability. The shift towards environmentally responsible packaging practices is not only driving innovation but also creating new opportunities for brands to differentiate themselves in a competitive market. Rigid boxes constructed from sustainable materials and designed for reuse align with modern consumers’ values, making them an attractive choice for businesses looking to enhance their brand image while contributing to environmental conservation.

Applications

Versatile Use Cases

Lid-and-base rigid boxes are widely utilized across various industries due to their adaptability and functionality. They serve as ideal packaging solutions for products requiring both protection and aesthetic appeal, making them suitable for high-end consumer goods, promotional items, and retail displays.

Frequent Use and Demonstration Items

These boxes are particularly beneficial for items that consumers need to access regularly, such as samples, testers, or product components. Their easy-to-open design enhances user experience, making them a practical choice for retail environments where product demonstration is common.

Luxury Goods Packaging

The rising demand for luxury goods has significantly influenced the rigid box market. Brands are increasingly opting for lid-and-base boxes to encapsulate their premium products. The aesthetic appeal of these boxes, combined with their superior protective qualities, makes them an essential part of maintaining brand image in the luxury sector. As brands look to differentiate themselves, the investment in high-quality packaging solutions becomes a priority.

Inclusivity in Design

Lid-and-base boxes are designed to accommodate a wide demographic, including elderly customers and individuals with limited dexterity. The universally easy-to-open nature of these boxes ensures inclusivity, enhancing customer satisfaction and broadening market reach.

Enhancing Brand Appeal

In addition to their practical uses, these boxes serve a vital role in branding and marketing. Their elegant designs can create a memorable unboxing experience, transforming the packaging into a storytelling medium that resonates with consumers. This aspect is crucial in competitive marketplaces where packaging acts as a key promoter of products.

Advantages

Exceptional Protection

One of the primary benefits of rigid packaging, including lid-and-base designs, is their superior protection for products. Constructed from durable materials such as chipboard and high-quality paperboard, these boxes provide exceptional resistance against external elements like pressure, impact, and temperature fluctuations. This robust protection is particularly critical for industries that handle delicate or high-value items, such as electronics, cosmetics, and pharmaceuticals.

Aesthetic Appeal and Customization

Lid-and-base rigid boxes are highly customizable, allowing brands to create visually striking packaging that aligns with their identity. These boxes can be finished with various printing techniques, embossing, debossing, and foil stamping to enhance their aesthetic appeal. The ability to incorporate intricate shapes and structural designs further facilitates brand recognition, making products stand out on retail shelves.

Cost-Efficiency in Shipping and Storage

The design of lid-and-base rigid boxes also brings significant economic advantages. Their collapsible nature can save more than 60% in shipping and storage costs compared to traditional packaging methods, making them a cost-effective option for businesses looking to optimize logistics.

Multi-Sensory Experience

Beyond mere visual appeal, lid-and-base rigid boxes can engage multiple senses, enhancing the consumer experience. The incorporation of textures, scents, and finishing enhancements creates a multi-dimensional unboxing experience that fosters a deeper connection with the brand.

Versatility in Product Presentation

These boxes provide versatility in how products are presented, accommodating various inserts, trays, and compartments to secure items while enhancing visual appeal. This versatility makes lid-and-base rigid boxes suitable for a wide range of products, from luxury goods to tech gadgets.

Sustainable Practices

Many lid-and-base rigid boxes are made from recyclable materials, aligning with the growing emphasis on sustainability in packaging. This not only helps reduce a brand’s environmental footprint but also appeals to eco-conscious consumers.

Comparison with Other Packaging Types

Overview of Packaging Options

In the packaging industry, three primary types of boxes are commonly used: corrugated boxes, folding cartons, and rigid boxes, each serving distinct purposes and presenting unique characteristics. Understanding the differences between these types can help businesses select the most suitable option for their products.

Rigid Boxes vs. Corrugated Boxes

Rigid boxes, often referred to as set-up boxes, are made from sturdy paperboard and provide a premium packaging solution characterized by their solid structure and high-quality finishes. They are typically four times thicker than standard folding cartons and are not designed to collapse, making them ideal for high-end items such as electronics, jewelry, and cosmetics. In contrast, corrugated boxes are constructed from corrugated fiberboard, featuring a fluted inner layer sandwiched between two flat linerboards. This design imparts significant strength and durability, making them the preferred choice for shipping goods that require protection during transit. While rigid boxes offer an elevated perception of quality and luxury, corrugated boxes excel in cost-effectiveness and recyclability, which are essential considerations for many businesses aiming to maintain sustainable practices. Corrugated boxes are generally more economical, making them suitable for shipping large volumes of products at a lower cost.

Rigid Boxes vs. Folding Cartons

Folding cartons are another popular packaging option, typically made from paper-board. They are designed to be shipped flat and assembled by the user, making them lightweight and easy to store. Unlike rigid boxes, folding cartons provide less structural integrity, which may limit their use for heavier or more delicate items. However, they are highly customizable and can be printed directly on the surface, offering businesses an opportunity for branding and product visibility at a lower price point than rigid boxes. In terms of aesthetic appeal, rigid boxes often surpass folding cartons, thanks to their premium materials and finishes, which convey a sense of luxury and quality. This makes rigid boxes particularly attractive for products in the high-end market.

Manufacturing Process

The manufacturing process of lid-and-base rigid boxes involves several meticulously planned steps that ensure high-quality output. Each stage is designed to optimize efficiency and enhance the final product’s presentation and functionality.

Material Management

Effective material management is essential to ensure that all necessary components are available during the manufacturing process. This includes the acquisition, inspection, inventory management, and purchasing of raw materials, such as chipboard and paperboard, needed for production. Identifying gaps in inventory and ensuring timely restocking can significantly reduce delays in production operations.

Production Steps

The production of rigid boxes can be broken down into several key steps:

Material Cutting

The first step involves precise cutting of chipboard and paperboard to the required dimensions. Accurate cutting is crucial for ensuring that all parts fit together perfectly during assembly.

Printing and Laminating

Once the materials are cut, the next phase includes printing the desired designs and applying protective coatings through laminating. This not only adds aesthetic value but also enhances durability.

Folding and Gluing

After printing, the cut pieces are folded into their designated shapes and glued at the joints to form the structure of the box. This step is critical as it defines the box’s integrity and usability.

Finishing Touches

To enhance visual appeal and user experience, additional processes such as embossing, foil stamping, or the incorporation of magnetic elements may be applied. These finishing touches are essential for creating a premium product that stands out in the market.

Quality Inspection

Every box undergoes a thorough quality inspection to ensure that it meets high standards before it is packaged and shipped. This step helps to identify any defects early in the production process, minimizing waste and ensuring customer satisfaction.

Transportation and Logistics

After manufacturing, the boxes are packed securely for transportation. Managing transportation costs effectively is crucial, which involves coordinating with suppliers and optimizing logistics to ensure timely delivery while minimizing expenses.

Sustainability Considerations

Today, sustainability is an integral part of the manufacturing process. Companies are increasingly adopting eco-friendly practices, such as using materials sourced from responsibly managed forests, reducing material waste through strategic design, and employing renewable energy in production processes. These initiatives not only appeal to environmentally conscious consumers but also contribute to the overall efficiency and reputation of the brand.

Market Trends

The market for lid-and-base rigid boxes is witnessing significant growth driven by several key trends. A primary factor is the increasing demand for sustainable packaging solutions, which aligns with global efforts to reduce environmental impact. Companies are progressively adopting eco-friendly materials, such as recycled paperboard and biodegradable options, to cater to the rising consumer preference for environmentally responsible products. The shift towards sustainability is not only a response to consumer demands but also a strategic necessity as brands seek to maintain market competitiveness and enhance their brand integrity.

Customization and Personalization

Customization is emerging as a crucial trend in the rigid box market. Advances in digital printing technologies are enabling brands to create high-resolution graphics and unique designs tailored to their specific branding needs. This personalization fosters stronger emotional connections with consumers, especially within premium and luxury segments, where packaging plays a vital role in the overall customer experience. The ability to offer bespoke packaging solutions is increasingly viewed as a value-add for brands aiming to differentiate themselves in a crowded marketplace.

E-commerce Growth

The rise of e-commerce has been a significant catalyst for the demand for lid-and-base rigid boxes. With the dramatic increase in online shopping, particularly during the pandemic, brands are investing in high-quality packaging that not only protects products during transit but also enhances the unboxing experience for consumers. The U.S. Census Bureau reported a 10% increase in e-commerce sales in 2023, underscoring the need for durable and aesthetically pleasing packaging solutions that meet the expectations of discerning online shoppers. As the e-commerce sector continues to grow, so does the demand for innovative packaging designs that reflect brand values and consumer preferences.

Competitive Landscape

The competitive landscape of the rigid box market is characterized by rapid innovation and the continuous introduction of new designs. Manufacturers are increasingly focusing on creating versatile packaging that accommodates various product types while also being aesthetically appealing. Key factors influencing competition include product quality, design innovation, and the ability to meet diverse market requirements. This competitive pressure encourages companies to invest in automation and advanced manufacturing techniques to improve production efficiency and reduce costs, thus enabling them to offer customized solutions at scale.

Regional Insights

Geographically, North America, Europe, and Asia-Pacific are leading contributors to the growth of the rigid box market. North America benefits from early technology adoption and a robust industrial base, while Europe’s growth is driven by regulatory mandates and green initiatives. In Asia-Pacific, particularly in countries like China and India, the market is booming due to rising disposable incomes and a growing middle class that increasingly seeks premium products. Emerging markets in the Middle East, Africa, and Latin America are also becoming attractive, supported by improving infrastructure and investments that are conducive to market growth.

Notable Manufacturers

The global rigid box industry features a competitive landscape dominated by established giants and emerging direct-to-consumer firms. Key players include Bemis Company, Inc., Amcor Limited, Coveris Holdings S.A., Reynolds Group Holding, Berry Plastics Corporation, Sonoco, Sealed Air Corporation, Silgan Holdings, Inc., Plastipak Holdings, Inc., Consolidated Container Company, DS Smith PLC, and Ball Corporation. These companies leverage advanced technology and innovative practices to maintain market leadership and cater to evolving consumer demands for luxury and sustainability.

Innovation and Quality Assurance

As manufacturers strive to meet rising consumer expectations, investment in cutting-edge technology and sustainable practices has become critical. For instance, many leading firms are adopting materials such as recycled cardboard and eco-friendly inks, aligning with global regulatory shifts towards environmental responsibility. Additionally, the focus on quality control is paramount; manufacturers are encouraged to implement robust quality assurance processes and comply with international standards, such as ISO 9001 and FSC certification. This focus ensures that production capacities and operational histories meet the expectations of both suppliers and consumers.

Competitive Strategies

To succeed in this dynamic market, it is advisable for businesses to solicit quotes from multiple suppliers to compare pricing, quality, and lead times. This approach not only fosters competitive pricing but also helps in identifying manufacturers with strong communication protocols and quality metrics, such as on-time delivery rates exceeding 97%. Embracing sustainable material choices and innovative construction techniques will further enhance brand differentiation and customer satisfaction in the rigid box sector.

Innovations and Technological Advancements

The evolution of lid-and-base rigid boxes has been significantly influenced by technological advancements across various facets of production, design, and materials. These innovations are reshaping the rigid packaging landscape, providing manufacturers with enhanced capabilities to meet consumer demands.

Automation in Production

High-speed automation technologies have revolutionized the manufacturing of rigid boxes, enabling mass customization and increased efficiency. Fully automated rigid box machines allow for rapid production cycles, reducing lead times and ensuring consistent quality across large volumes of output. The integration of Industry 4.0 principles is further enhancing operational sophistication, making it possible for companies to produce customized rigid boxes at a competitive cost.

Material Innovations

The introduction of innovative materials and construction techniques is pivotal in the development of modern rigid boxes. Manufacturers are increasingly adopting sustainable materials such as recycled cardboard and biodegradable substrates, aligning with a growing emphasis on environmental responsibility. Additionally, the use of eco-friendly inks and smart technologies, like embedded RFID tags, not only enhances product tracking but also supports brand differentiation in a crowded market.

Customization and Design

Advancements in digital printing technologies have facilitated high-resolution graphics and unique designs on rigid boxes, allowing for greater customization and personalization. This trend is particularly beneficial for premium and luxury segments, where brand storytelling and emotional connections with consumers are paramount. Moreover, manufacturers are experimenting with innovative shapes and textured finishes to elevate the aesthetic appeal and perceived value of their products.

Sustainability Considerations

As sustainability becomes increasingly crucial in consumer and brand decision-making, innovations in rigid box design also prioritize eco-friendly features. The shift towards simpler structures, such as lid and base boxes, makes it easier for manufacturers to produce recyclable and sustainable packaging without compromising on visual appeal or functionality. This trend is reflected in the growing demand for materials that minimize environmental impact while maintaining a luxury feel.

Future Outlook

The future of lid-and-base rigid boxes is poised for significant transformation driven by various trends and innovations in packaging. One of the most prominent trends is the increasing demand for sustainable packaging solutions. As consumers and brands become more environmentally conscious, there is a growing emphasis on utilizing eco-friendly materials, such as recycled rigid paperboard, and reducing plastic usage in packaging designs. Companies are focusing on producing boxes with recyclable features and minimal environmental impact, which enhances their appeal to consumers who prioritize sustainability. Additionally, technological advancements are set to play a vital role in the evolution of rigid boxes. The integration of digital features, such as QR codes and augmented reality (AR), allows brands to engage consumers more interactively and provide additional information about their products. This trend not only enhances consumer experience but also promotes brand loyalty and integrity. Customization will also continue to be a key focus area. As brands seek to differentiate themselves in a competitive market, offering personalized packaging solutions that align with their brand identity will be crucial. The ability to create unique, aesthetically pleasing, and functional designs can significantly impact consumer perception and purchasing decisions. The market is projected to expand at a compound annual growth rate (CAGR) of 1.8% from 2024 to 2034, with a predicted market value increase from USD 80.6 billion in 2024 to USD 96.3 billion by 2034. India is anticipated to emerge as a leading market, driven by its rapid economic growth and increasing disposable income, which is expected to fuel demand for high-quality packaging solutions.